Some individuals aspire to build the 1955 Model stereo tube amplifier themselves, either by sourcing the components individually or opting for a complete kit. However, they often encounter challenges when attempting to recreate its retro, point-to-point assembly, also known as ‘câblage en l’air’ in French.

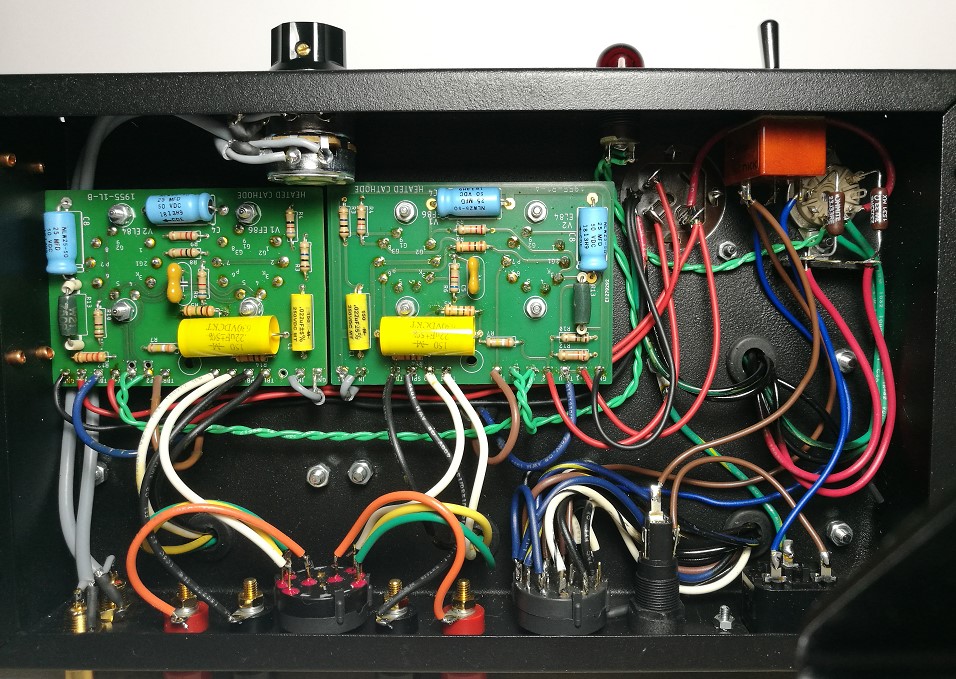

To simplify the assembly of this tube amplifier, I have developed a pair of Mullard 3-3 Printed Circuit Boards (PCBs) that seamlessly fit the pre-drilled chassis of the 1955 Model amplifier.

The printed circuit board was invented by an Austrian engineer, Paul Eisler, in England in 1936. He obtained a British patent for the concept in 1943.

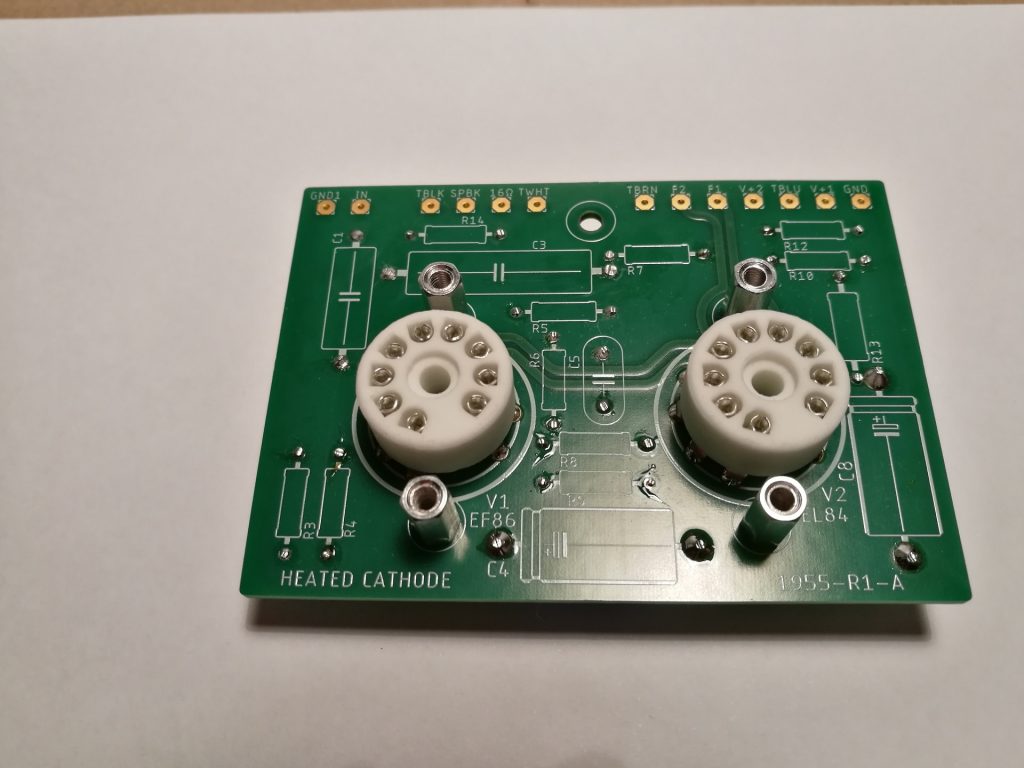

These printed circuit boards have the passive components drawn on both sides. However, it’s important not to install the resistors and capacitors on the same side as the tube sockets. Doing so would result in a fully functioning circuit, but it won’t fit correctly within the 1955 Model tube amplifier chassis due to the larger diameter of the 0.22 uF, 630 V capacitor C3.

The following image serves as an example of what to avoid when mounting the printed circuit board in a 1955 Model amp chassis. Nevertheless, this configuration is suitable if you intend to affix the circuit to a flat metal, wooden, or plastic surface, such as within a vintage wooden radio or record player case.

These printed circuit boards have the names of the electronic tube electrodes printed for the EL84 and EF86 tubes: cathode, plate, and grids, so that the tube electrodes can be easily referenced, and the operating voltages can be measured with the chassis open.

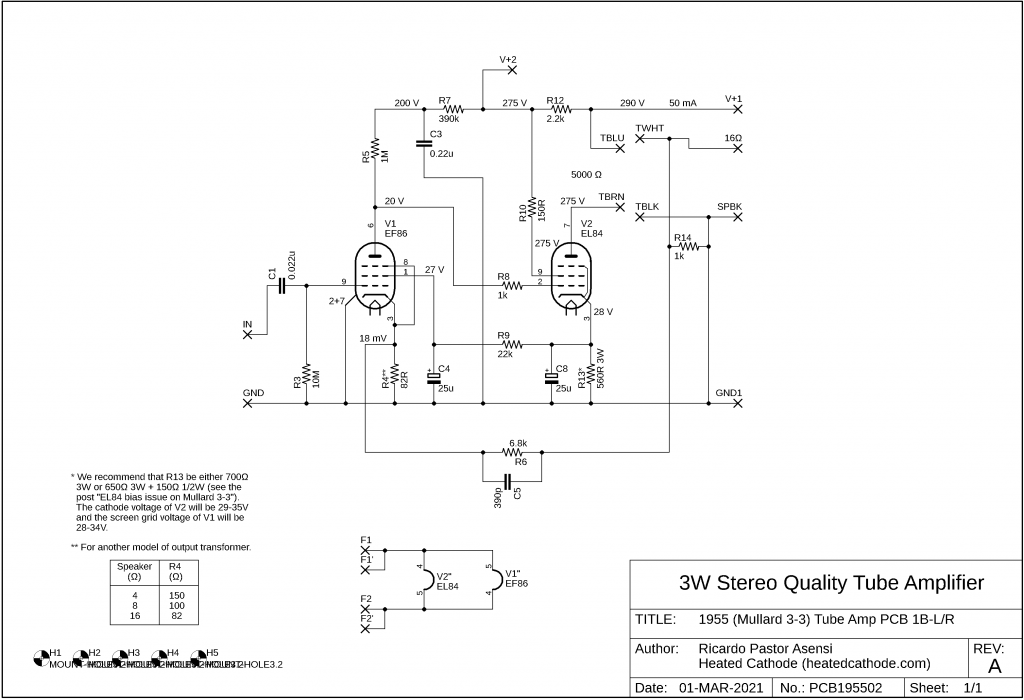

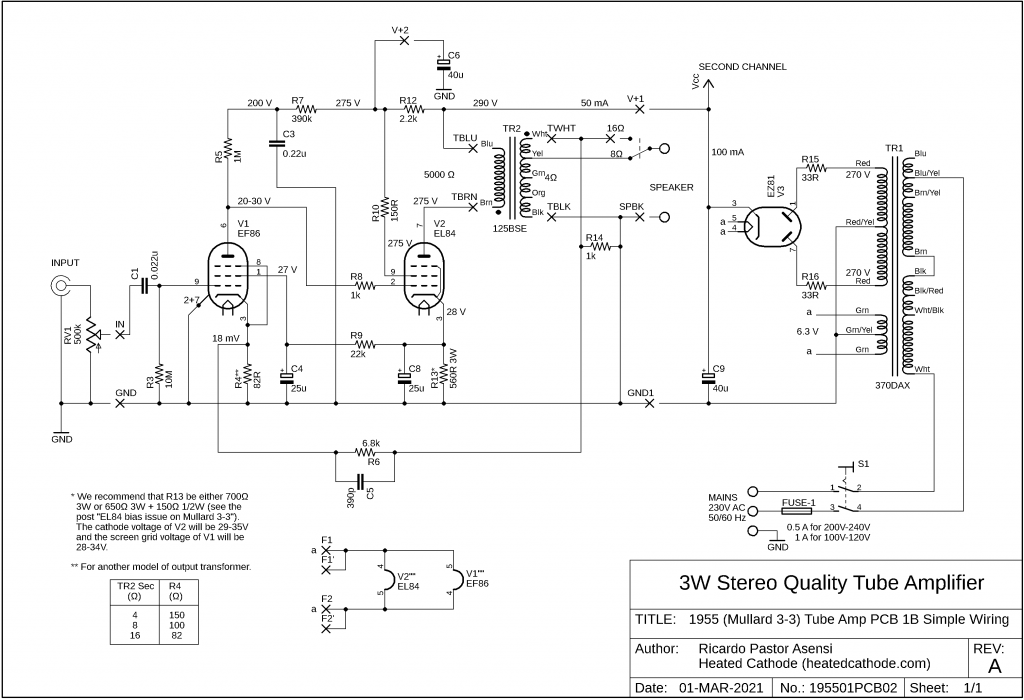

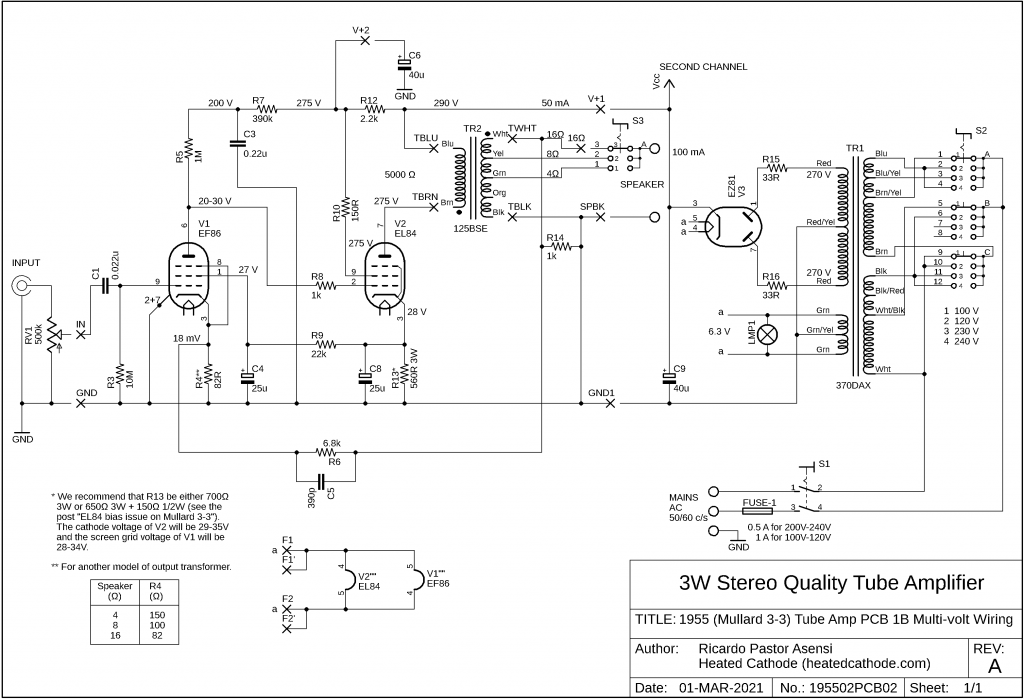

Below you can find the schematics.

Download wiring schematic in PDF

Download wiring schematic in PDF

The PCB measures 83 x 59 mm.

To complete the Model 1955 stereo amplifier, two separate symmetrical printed circuit boards are required, one for the left channel (L) and one for the right channel (R). As they are separate printed circuits, better insulation between channels is achieved, and the single signal ground to chassis connection is maintained as an essential condition to avoid the hum due to the equipment’s alternating current power supply.